arguably, the top two contenders in the electric vehicle industry are:

Tesla

, operated by Elon Musk and based in Austin, Texas; and

BYD, a Chinese automaker achieving substantial global sales, is making significant progress.

Not unexpectedly, each of these producers adopts a somewhat distinct strategy when it comes to developing, constructing, and producing electric vehicles, which naturally includes variations in their battery pack designs.

NMC Compared to LFP, Round Cells Versus Blades

As stated in an article from

SciTechDaily.com

, researchers at

Cell Reports Physical Science

they have examined the batteries utilized by both Tesla and BYD, uncovering several interesting distinctions between them. In brief,

Tesla’s 4680 cells, which use a nickel-manganese-cobalt composition (NMC),

These designs prioritize performance and high energy density. In contrast, BYD’s blade design uses more economical materials (specifically lithium iron phosphate, or LFP) and focuses on maximizing spatial efficiency.

These methods represent two distinct paths to arrive at the same endpoint, despite being intriguingly different.

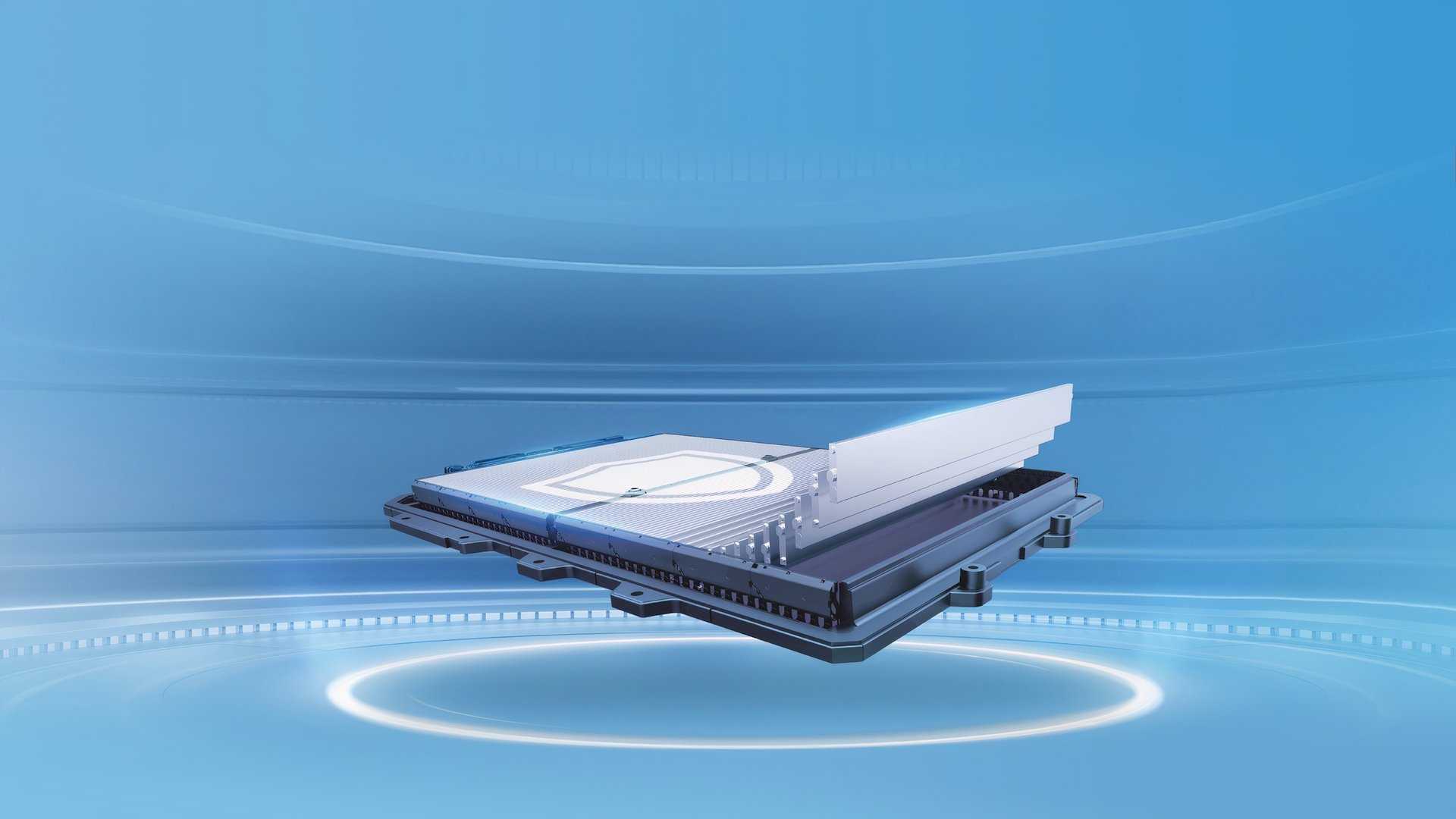

BYD’s battery configuration

features superior thermal management. It is said that Tesla’s model generates approximately double the amount of heat under a certain workload compared to BYD’s setup. Consequently, this necessitates roughly twice the cooling capability.

Additionally,

BYD’s electrodes include two types of welding techniques.

As mentioned in the Cell Reports Physical Science article, “One benefit of this method is that laser welding requires access to just one side of the busbar, with ultrasonic welds ensuring proper layer-by-layer contact before undergoing laser welding.” Furthermore, “It enables a highly compact contacting arrangement where the contacts occupy merely the space equivalent to a single stacked electrode foil fold.” Conversely, “Tesla’s 4680 cell electrodes and their associated foils have angled cuts at both ends which are subsequently overlapped to form a contact area,” thus implementing a tab-free configuration.

In terms of energy density, Tesla clearly leads with the 4680 cell, thanks to its potent NMC chemistry. This battery achieves approximately 241 watt-hours per kilogram of mass at the cell level. In contrast, the BYD model has a rating of only 160Wh/kg. It’s worth noting that both designs employ graphite anodes devoid of silicon dioxide.

Subtle But Substantive Differences

While they might appear quite alike at first glance, electric vehicles actually possess significantly distinct engineering traits. Variations in battery composition and setup can greatly influence the performance of these cars, leading to various compromises based on specific design choices. Similar dynamics occur within conventional gasoline-powered engines; however, these differences aren’t always as apparent as those between contrasting engine types such as Ford’s 5.0-liter Coyote V8, which features an overhead camshaft, and GM’s pushrod LT series. Despite both being powerful options, their inner workings—and numerous additional elements—vary immensely. In the realm of electric vehicles, comparable contrasts persist, albeit more subtly compared to high-performance gas engines.